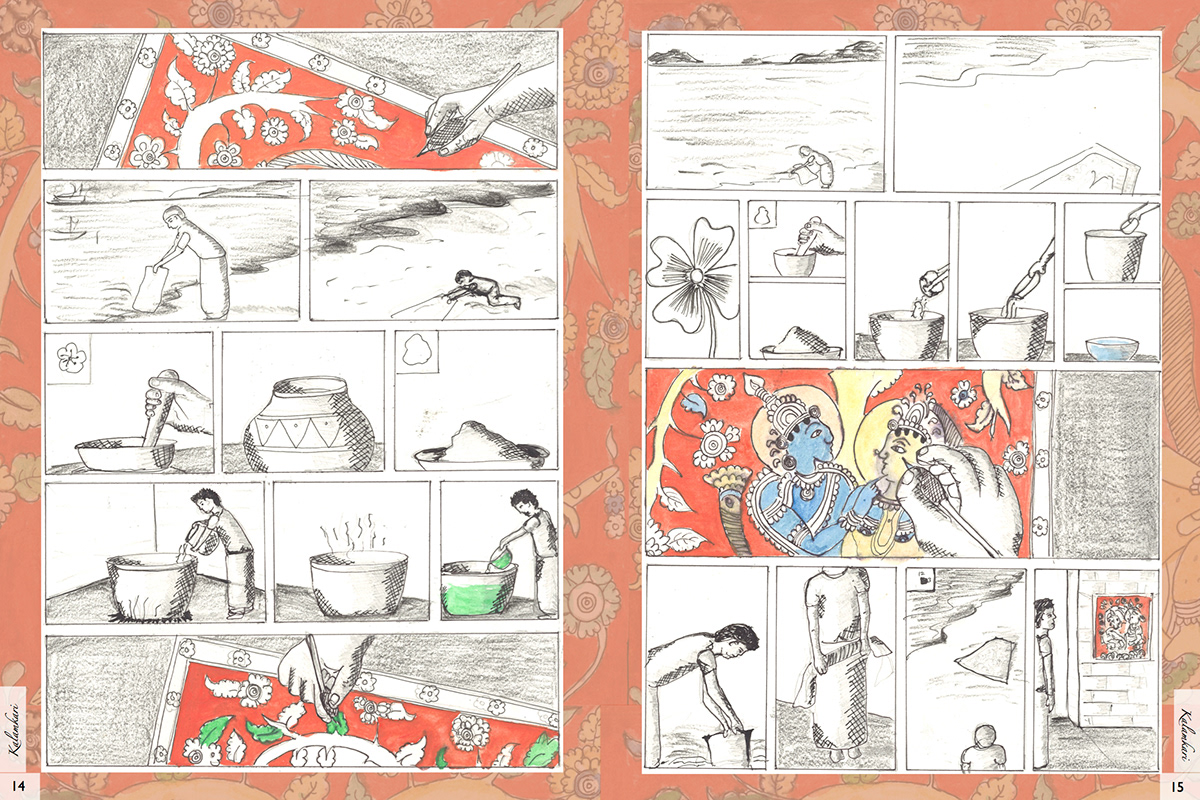

The cover page and the back for the process of making a hand painted kalamkari process

Kasim kaaram-Iron black color solution prepared using rusted iron filings, cane jaggery and palm jaggery. These materials are dissolved in water in a closed earthen pot and allowed for fermentation for 10 days

They cut,dry and sharpen the bamboo and tie the thread around the bamboo to make the kalam.

After 10 days the solution is filtered and the iron filings are taken out. The prepared Kasim kaaram is used for drawing outlines and to fill black color. The tamarind stems are burned and made into charcoal. This charcoal is used for initial sketching.

They squeeze the lemon the remove the extra outline.

The washed cloth is then treated in a solution which is made by mixing Myrobalan bud paste (Karakapinde locally), Myrobalan flower paste (Karakapoovulocally) and buffalo milk.

The buffalo milk is used to treat the cloth which helps to avoid color spreading.

Pomegranate skin is dried and mixed with alum to obtain light yellow color.

Myrobalan flower and alum are grounded into powder and mixed with water. This solution is boiled and cooled to obtain yellow color.

Chavalakodi root powder and alum is mixed with water to obtain red color

Blue is extracted from natural indigo.

The cotton cloth after going through so many washes. It is washed one last time and dried and is finally sent out for sale.

The final kalamkari hand painting of Radha krishna.